Introduction

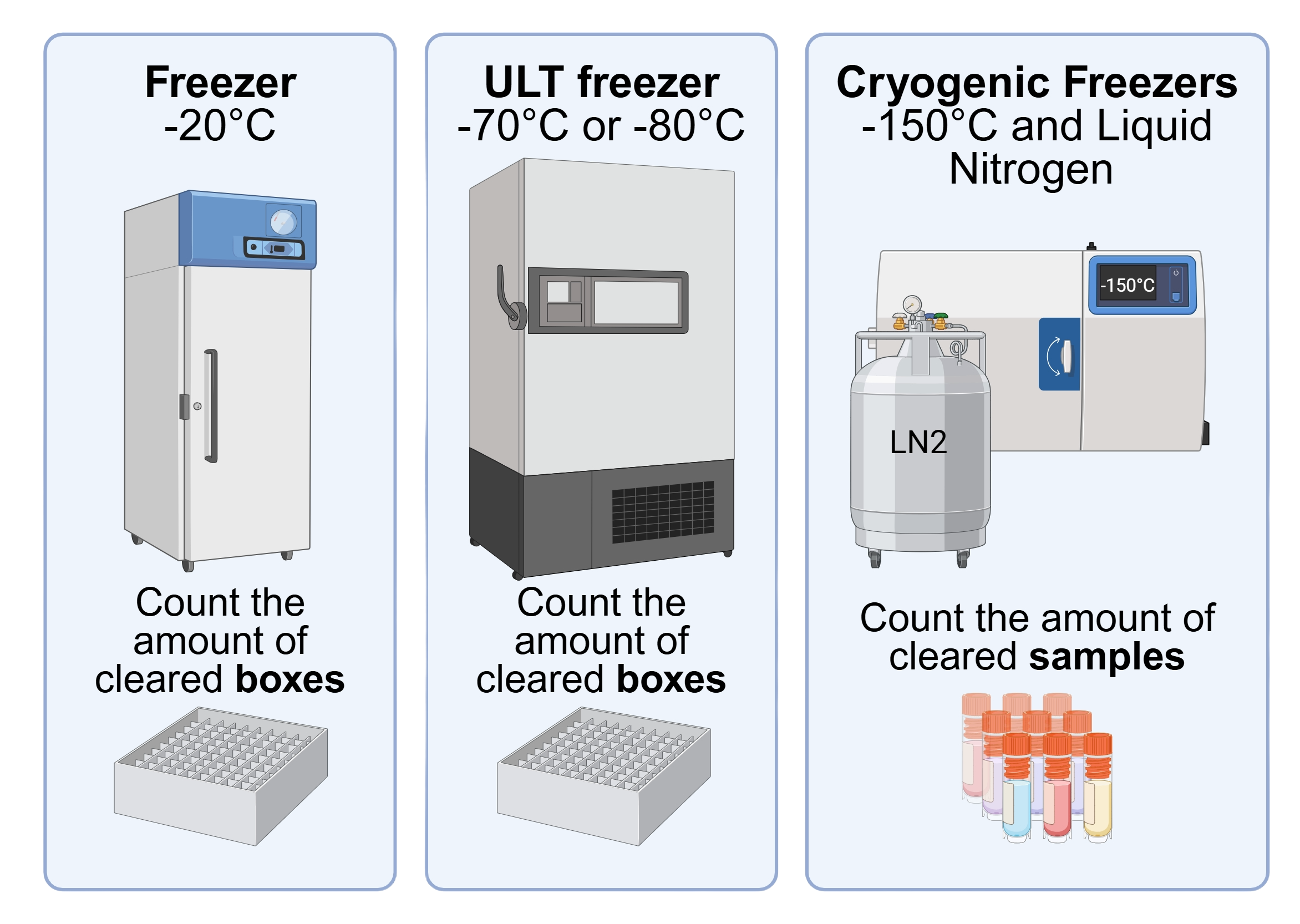

Cold storage is essential in scientific research, but it also cases a high energy demand for laboratories. Ultra-low temperature (ULT) freezers operating at -80°C use about as much electricity as two average Dutch households. Freezers at -150°C or systems using liquid nitrogen consume even more. In addition, hospitals and research institutes have a large number of -20°C freezers, which also often use a lot of electricity.

During the National Freezer Challenge, action is taken to reduce CO₂ emissions and save costs. By cleaning out unnecessary or outdated samples, valuable storage capacity is freed up, reducing the need for new freezers. In addition, freezer contents can be consolidated, which in some cases may result in freezers being shut down.

On this page, you will find all the necessary information about the National Freezer Challenge 2025!

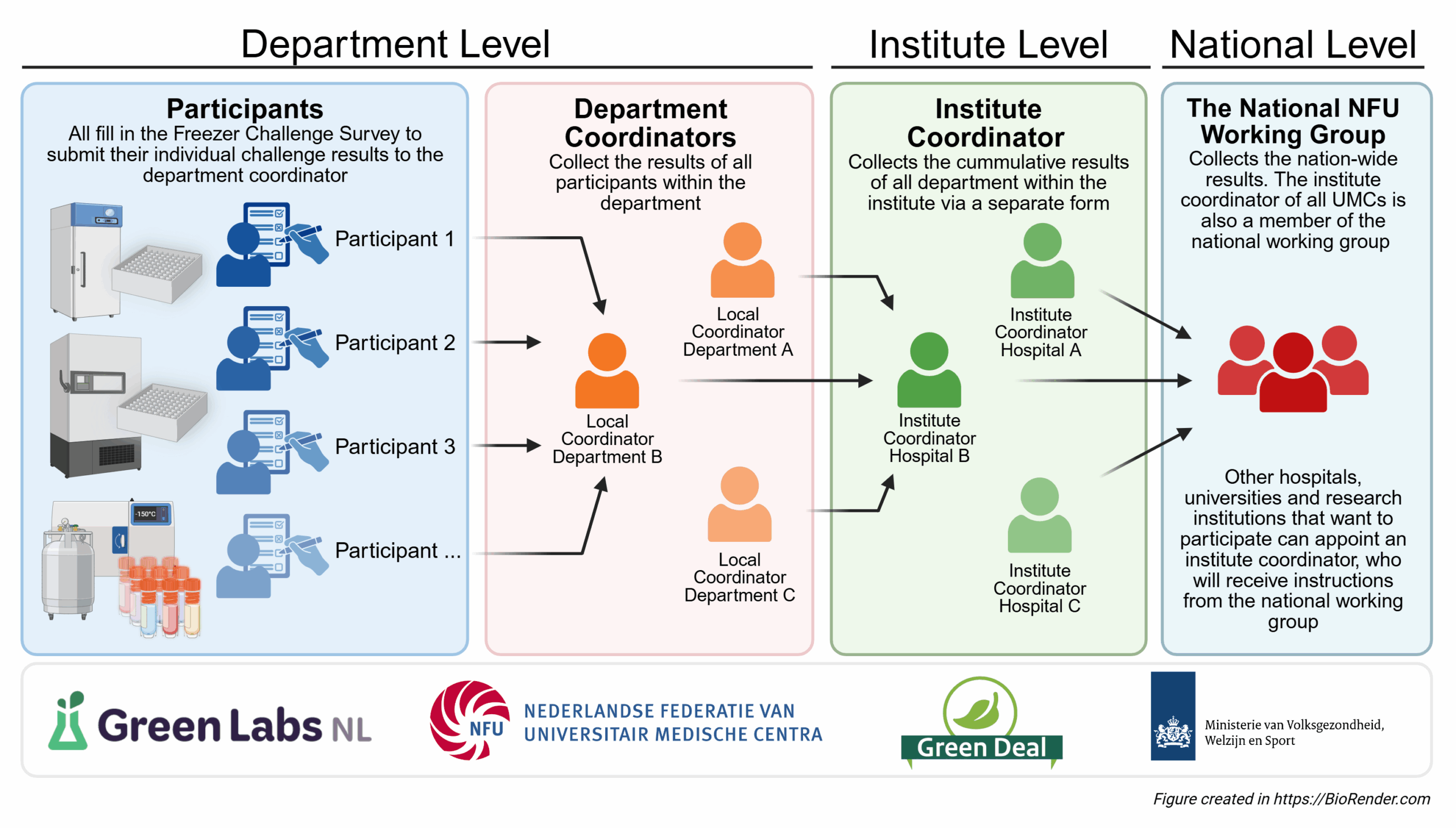

The National Freezer Challenge takes place at three levels:

Department

The Freezer Challenge participants clean out the freezers and keep track of how many boxes they have emptied using a scoring sheet. They share their results with a designated departmental coordinator from their department. This can be a lab coordinator, a local green team or an enthusiastic colleague that wants to coordinate this initiative locally. The departmental coordinators serve as the point of contact within the department for the challenge and will collect the results from staff members in their department via a Microsoft Forms form.

Institute

The institute coordinator collects the results from all departments within the participating institute and shares them with the national working group. The institute coordinator is also the point of contact within the institute for questions about the challenge. In addition, the institute coordinator determines the details of the challenge within the institute, for example, whether an internal prize will be awarded to the department that has shown the greatest commitment to the challenge.

National

The national working group of the Freezer Challenge, part of the NFU working group “Sustainable Laboratories”, compiles all national results, which will be presented at the beginning of 2026. In addition, several clean-up initiatives from participating institutes will then be highlighted nationwide. Every UMC in the Netherlands is represented in this working group and already has an assigned institute coordinator. Do you not work in a UMC but would still like your institute to participate in the challenge? Then you can register your institute for participation via Green Labs NL using this link.

Promo Video:

Participating Institutes

Would you like to participate in the Freezer challenge with your institute? Register your institute using this form

National Freezer Challenge Resources

Information for Participants

- Manual for Participants – contains all the information for participants of the Freezer Challenge

- Freezer Challenge Scoring Sheet – An optional document which you can use during the challenge to keep track of your cleaning results. For an example of a filled-in scoring sheet, click here.

Communication material

- Powerpoint slides Freezer Challenge

- Freezerchallenge 2025_Poster (ENG)

- Freezerchallenge 2025_Poster (NL)

All other required documents will be shared by your local Freezer Challenge coordinator

Frequently Asked Questions

About the Challenge

About the Sustainable Use of Freezers

People working on this project

Joep Sprangers

UMC Utrecht

Aram de Haas

Amsterdam UMC

Mandy Erkelens

Leiden UMC

Esmee Kiewiet-Kasteleijn

Erasmus MC Rotterdam

Fred van Opzeeland

Radboud UMC Nijmegen

Anouk de Boer-Poelstra & Megha Pandey-Upadhyay

UMC Groningen

And with support from all other members of the National NFU working group ‘Sustainable Laboratories’